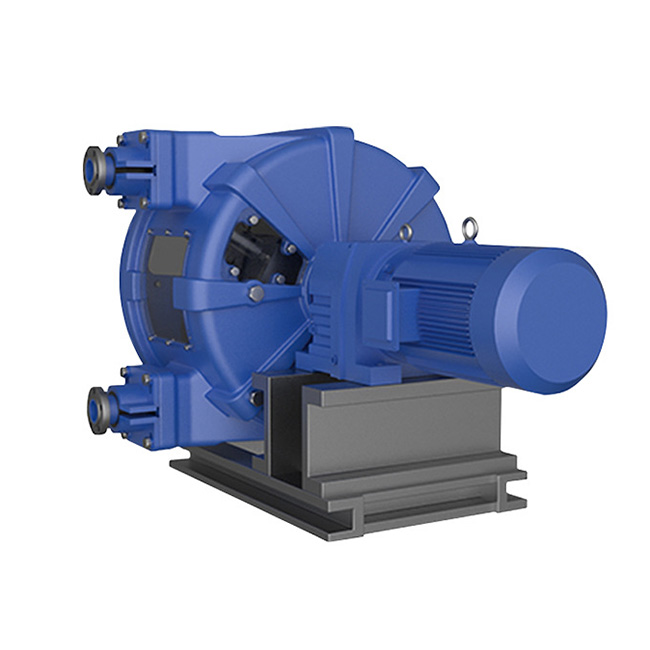

Product name: oil pipeline pump

Product model: KSY type

Product flow: 54~5500m3/h

Product head: 80~1080m

Product material: cast iron, cast steel, etc.

Pump packing and sealing principle: The medium conveyed by the pump is generally a liquid substance with high fluidity. Generally, due to the relationship of the bearings, most pumps except magnetic pumps, canned pumps and other special pumps need to consider the dynamic sealing structure. The basic principle of packing seal is introduced as follows: packing seal generally consists of packing gland, stuffing box, packing, liquid seal ring and bolts. Its working principle is: the pre-tightening force generated by the compression bolt causes the packing to produce axial compression deformation, and at the same time causes the packing to expand radially. Due to the radial constraints of the shaft surface and the inner surface of the stuffing box, the gap is filled and the result is achieved. sealing purpose. Some sealing structures add a packing ring to the packing and divide the packing into two sections. The purpose is to make the radial force generated by the packing uniform. In order to ensure sufficient lubrication and cooling, lubricating sealing liquid can be injected into the inlet of the liquid sealing ring. .

【Overview of KSY type oil pipeline pump】: KSY type oil pipeline pump series products can provide complete sets of products for oil pipelines with an annual output of 20 million tons. This product has the following characteristics.

1. High reliability, bearing body parts have two structures, good heat dissipation.

2. High-efficiency hydraulic model is adopted for the hydraulic overflow part. 5-8% more efficient than old pipeline pumps.

3. High degree of generalization of parts and components.

4. The selection of materials is refined, mainly Class II materials, and the bearing body and other components are cast iron.

Working principle: The common centrifugal pump connects the impeller shaft of the pump with the electric shaft through the coupling to achieve the driving purpose, and the impeller and the electric motor rotate together to work. The canned pump is a non-sealed pump. The rotor and stator of the motor are separated by a shielding sleeve. The pump and the driving motor are sealed in a pressure vessel filled with the pumping medium. This pressure vessel has only a static seal and is sealed by A point winding provides the rotating magnetic field and drives the rotor, which operates in the medium being conveyed. This structure makes the canned pump completely leak-free.

Selection (model): The selection of the pump is mainly based on the conveying medium, working conditions, flow, head and its variation law. Generally refer to the basic principles:

1. Determine the flow and head according to production needs.

2. Select the pump type with good performance and strong adaptability and guarantee with the flow and head changes required by the project. First of all, in a certain line of products, pumps with high efficiency, good suction performance, and a wide range of use should be selected. When there are multiple pump types to choose from, technical and economic analysis should be carried out, and the best ones should be used. When the actual working conditions require a large head change, a pump with a steep H-Q curve should be used; when a large flow change is required, a pump with a gentle H-Q curve should be used.