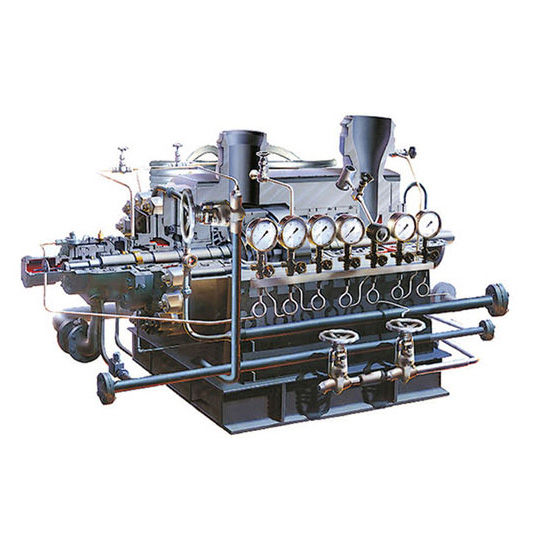

According to the requirements of thermal power units, the boiler feed pump unit must ensure safety, reliability, high efficiency and high level of controllability during operation. The double simplified CHT pump produced by our factory has the following characteristics: 1. The number of stages is small; 2. The rigid shaft; 5. The maintenance time is short, and it can be put into operation in a short time; 6. The efficiency of the pump is generally above 80%;

In order to ensure the cavitation characteristics of the pump, a low-speed front pump is provided.

Consult nowOverview:

According to the requirements of thermal power units, the boiler feed pump unit must ensure safety, reliability, high efficiency and high level of controllability during operation. The double simplified CHT pump produced by our factory has the following characteristics:

1. The number of stages is small;

2. Rigid shaft;

3. The axial thrust is jointly borne by the hydraulic leveling mechanism and the thrust bearing, and can compensate each other;

4. Can adapt to short-term cavitation;

5. The maintenance time is short, and it can be put into operation in a short time;

6. The efficiency of the pump is generally above 80%;

In order to ensure the cavitation characteristics of the pump, a low-speed front pump is provided.

The rotation direction of the pump is clockwise when viewed from the transmission direction (it can also be manufactured by counterclockwise rotation).

Introduction to structure

CHTA:

The CHTA pump is a double-shell horizontal multi-stage centrifugal structure.

CHTA type pump simplified (101) pump cover (102; is a forging, the surface in contact with the liquid is covered with austenitic stainless steel welding layer, the inlet and outlet of the pump are upward, and the inlet and outlet of the pump can also be downward according to needs The middle section (104) of the inner casing, the suction section (103), the guide vanes (106), are made of chrome steel, the impeller sealing ring {121), the guide vane bushing (117), and the shaft (201) in the rotor part ), impeller (202), balance disc (213) are all made of special materials, 95% of the axial force is borne by the balance device; the remaining axial force and the additional axial force generated under special conditions are Thrust bearing to bear. The pump shaft seal is a mechanical seal, the heat generated by the friction pair is taken away by the forced circulating water, and the circulating water is filtered through a specially designed cooler and filter to ensure the cleanliness of the circulating water quality (see Figure 2). The radial bearing is four oil wedges, which are forced to lubricate.

CHTC:

The structure of the pump barrel is suitable for the pump core to be pulled out quickly, which saves the maintenance time, and the barrel is welded in the pipeline system. The pressure boundary is suitable for 100% volume detection.

Computer-aided design of cylinders with varying pressure and temperature.

The axial force is borne by the balance disc and thrust bearing, which makes the pump have high reliability and safety.

Using the best model design.

Satisfy the operation experiments of thousands of pumps in thermal power stations.

It can meet the cold state or standby state start.

The design of the pump unit allows the mechanical seal and balance disc to be removed without removing the motor.

Equipment for measuring rated axial force (pump precaution).

CHTZ:

a.CHTZ type water supply pump is a horizontally open double shell structure with impellers arranged in the same direction. It is different from the horizontally open structure with impellers arranged in the same direction of foreign advanced companies. Its advantages are to shorten the radial and axial dimensions and reduce the air Ask the transition flow channel, the pump volume is reduced, the overall reliability is high, and the space is small;

b. Under the condition that the external dimensions, pump cylinder and rotor of the original CHTA feed pump remain unchanged, the pump core of CHTZ can be interchanged with the pump core of the original CHTA, which provides favorable conditions for the structure to be used in power plants as soon as possible. , with a high degree of generalization and applicability;

c.CHTZ type water supply pump horizontal open inner shell is an integral structure, compared with the pump core matched with segmental multi-stage guide vanes and middle section, it eliminates the dynamic and static errors caused by many matching gaps. Greatly improves the overall structural rigidity of the pump core and improves the reliability of the pump set;

d. Compared with the segmental feed water pump, the pump core of the CHTZ feed pump can be quickly drawn out, and without the need to disassemble the impeller step by step (hot-fitting or sliding), the horizontal split inner shell can be opened to quickly repair all levels. The dynamic and static parts are easy to assemble, disassemble and maintain, which greatly shortens the maintenance time of the feed pump, which is convenient for users, improves the utilization rate of the boiler, and creates more benefits for the power plant;

e. The effective element method is used to carry out structural analysis, calculation and design of the horizontally split inner shell, fully considering the requirements of strength and rigidity and the minimum deformation caused by the uneven temperature field to the inner shell;

f. The wet circumference of the flow channel of the feed pump is small, which is convenient for lighting, which is beneficial to improve the efficiency of the pump;

g. After the rotor is dynamically balanced, it does not need to be disassembled, so that the original dynamic balance accuracy of the rotor can be optimally maintained, which is more beneficial to the reliable operation of the pump;

h.CHTZ type feed pump implements ZN57083 quality control regulations;

i. The external dimensions, driving mode, mechanical sealing system, monitoring and protection and performance parameters of the pump set are all the same as those of the CHTA type high pressure boiler feed pump