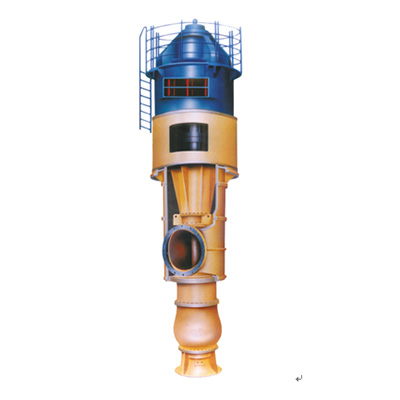

H-type vertical diagonal flow pump is a new variety developed by our factory with the introduction of foreign advanced technology.

The vertical diagonal flow pump is especially suitable for the circulating water pump of the power plant.

Consult nowH-type vertical diagonal flow pump is a new variety developed by our factory with the introduction of foreign advanced technology.

The vertical diagonal flow pump is especially suitable for the circulating water pump of the power plant.

Performance parameters:

Flow (Q) 0.1~54000m sand

Head (H) 4~95m

Features:

1. Small size, light weight, small footprint of the unit, no need to irrigate before starting.

2. High efficiency, the pump efficiency is about 80~90.7%.

3. Good cavitation performance.

4. Safe and reliable, long service life. It is suitable for conveying water below 55 kernels. liquids such as seawater. Specially designed pumps can also transport sewage, brine and liquids below 85°C.

Shaft seal:

The upper end of the pump is provided with packing, which is sealed with soft packing, or mechanical seal or parking seal. The shaft seal is fitted with a replaceable bushing to protect the pump shaft.

Transmission:

The pump is directly driven by an electric motor through a rigid coupling. Seen from the drive end, the pump rotates clockwise. Generally speaking, the pump is allowed to reverse in a short time. When the user does not allow the pump to reverse, the anti-reverse mechanism can also be added.

Note: Some pumps are connected by elastic coupling (when the pump itself has thrust bearing).

Structure:

Type H is a single or two-stage vertical centrifugal or oblique flow impeller with guide vane pump:

1. How to connect the pump. The single base unit pump is directly connected and installed on one base. Double foundation: The pump is installed on its own foundation. Among them, the outlet pipe of the pump is either on the basis of the pump or under the basis of the pump.

2. The suction pool of the pump is a wet pit type: the pump is directly inserted into an open water channel (according to user needs, it can also be designed as a dry pit structure).

3. The pump can adopt an adjustable structure, the blades can be directly adjusted during operation, and the blade adjustment range is +2.75°~-10°

4. The bearings in the middle of the pump are water lubricated rubber bearings, BBF bearings or Sailong bearings.

5. The pump shaft is provided with a shaft protection tube, which is filled with clean pressure water to lubricate the bearings. Under special circumstances, the copper alloy bearing can also be lubricated by oil, or the anti-dry-wear bearing pump itself can be used to lubricate the medium.

6. The pump can be divided into rotor (impeller, shaft, protective tube, bearing, shaft seal, etc.) and double-shell type (see 1400HTC, 1400HB, 1600HK and 1800HK type spring structure diagram) and non-extractable single-shell type. Shell structure.

7. Most of the axial thrust of the pump is borne by the thrust bearing of the motor, and some pumps with a discharge diameter of 350-1000 mm can be designed to bear the axial force by the thrust bearing of the pump itself as required.